Thursday, February 5, 2015

Wednesday, February 4, 2015

Tuesday, February 3, 2015

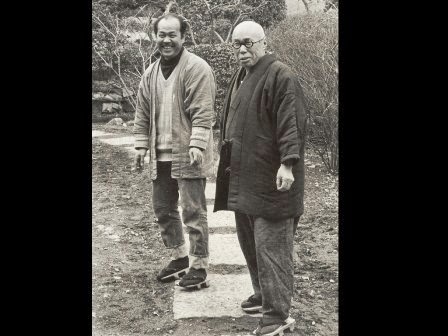

Photos Of Tatsuzo Shimaoka with his Deshis, his teacher Shoji Hamada and as a Young Man.

During his apprenticeship, Shimaoka used to stand behind his teacher while he was throwing and imitate his movements on the wheel, while standing behind him. Mrs. Hamada once told Shimaoka that her husband Shoji would talk to Yanagi in his sleep. Shimaoka admired that friendship and said he wished he had a friend like Yanagi was to Hamada.

I once read that my Grand Sensei Shoji Hamada said, "The philosopher has Beauty, but the craftsman only has his character."

I once read that my Grand Sensei Shoji Hamada said,

"The philosopher has Beauty, but the craftsman only has his character."

Monday, February 2, 2015

Axe Handles

We own an artist's proof of our friend Mayumi Oda's Treasure Ship Snow Goddess we bought at a Mnnesota Zen Center Spaghetti Dinner & Auction.

It is the first thing I see every morning when I get up.

Axe Handles

BY GARY SNYDER

One afternoon the last week in April

Showing Kai how to throw a hatchet

One-half turn and it sticks in a stump.

He recalls the hatchet-head

Without a handle, in the shop

And go gets it, and wants it for his own.

A broken-off axe handle behind the door

Is long enough for a hatchet,

We cut it to length and take it

With the hatchet head

And working hatchet, to the wood block.

There I begin to shape the old handle

With the hatchet, and the phrase

First learned from Ezra Pound

Rings in my ears!

"When making an axe handle

the pattern is not far off."

And I say this to Kai

"Look: We'll shape the handle

By checking the handle

Of the axe we cut with—"

And he sees. And I hear it again:

It's in Lu Ji's Wên Fu, fourth century

A.D. "Essay on Literature"-—in the

Preface: "In making the handle

Of an axe

By cutting wood with an axe

The model is indeed near at hand."

My teacher Shih-hsiang Chen

Translated that and taught it years ago

And I see: Pound was an axe,

Chen was an axe, I am an axe

And my son a handle, soon

To be shaping again, model

And tool, craft of culture,

How we go on.

The Firing.

for Les Blakebrough and the memory of John Chappell

by Gary Snyder

Bitter blue fingers

Winter nineteen sixty-three A.D.

showa thirty-eight

Over a low pine-covered splay of hills in Shiga

West-south-west of the outlet of Lake Biwa

Domura village set on sandy fans of the sweep

and turn of a river

Draining the rotten-granite hills up Shigaraki

On a nineteen-fifty-seven Honda cycle model C

Rode with some Yamanashi wine "St. Neige"

Into the farmyard and the bellowing kiln.

Les & John

In ragged shirts and pants, dried slip

Stuck to with pineneedle, pitch,

dust, hair, woodchips;

Sending the final slivers of yellowy pine

Through peephole white blast glow

No saggars tilting yet and segers bending

neatly in a row--

Even their beards caked up with mud & soot

Firing for fourteen hours. How does she go.

Porcelain & stoneware: cheese dish. twenty cups.

Tokuri. vases. black chawan

Crosslegged rest on the dirt eye cockt to smoke--

The hands you layed on clay

Kickwheeld, curling,

creamed to the lip of nothing,

And coaxt to a white dancing heat that day

Will linger centuries in these towns and loams

And speak to men or beasts

When Japanese and English

Are dead tongues.

Sunday, February 1, 2015

Thursday, March 13, 2014

Sponging Bisque. (something I wrote on an Email List)

I was the main bisque sponger during my apprenticeship. It is a much more accurate application than spraying or dipping, and in the case of dusty bisque from sitting around or if you do inlay (which creates dust), it is more efficient in getting the dust off.

Especially in the noborigama bisque, firing temps vary to a large degree. The highest temp was only dull red.

Bisque temp is a factor in absorbancy, but so is bisque thickness. By sponging, you can cause more water do go into soft bisque or thick pots.

We always started glazing the smallest, thinnest pots first. They require glaze with less water in it. As we moved to larger, thicker work, water was added to the glazes. We adjusted up to a dozen times. We always scratch tested the glaze to have an accurate idea about how thick the glaze application was. Its thickness was important over inlay, so that the inlay would not be obscured or undercovered.

Not only that, from 25% to 5% kaolin was added to the ash glaze, depending upon which kiln it went in and what place in the kiln, the hottest spots requiring the most kaolin.

Warren MacKenzie watched us glaze one time and was amazed by the process, because all these adjustments occur in silence.

Wednesday, March 12, 2014

Subscribe to:

Posts (Atom)